Are you looking for the right solar panel to charge your battery? Here are some tips to help you choose the right one.

When selecting a solar panel to charge your battery, it is essential to ensure that the voltage of the solar panel is greater than the fully charged voltage of the battery by 20-30%. For instance, a 6V battery requires an 8-9V solar panel, and a 12V battery requires a 15-18V solar panel.

Another crucial factor to consider is the solar panel’s Voltage Open Circuit (VOC), which should be between 1.4 and 1.8 times the nominal battery bank voltage. Suppose you have a 24-volt system, in that case, the VOC should be between 33.6V and 43.2 volts.

In addition to voltage, also consider the amperage of the solar cell. The amperage will fluctuate with sun exposure and determine how long it takes to recharge the battery. By keeping these factors in mind, you can choose the perfect solar panel to power your battery.

Choosing the right solar panel for your battery is crucial to ensure optimal performance and longevity. Keep these tips in mind when selecting your solar panel, and you’ll be on your way to powering your devices with renewable energy.

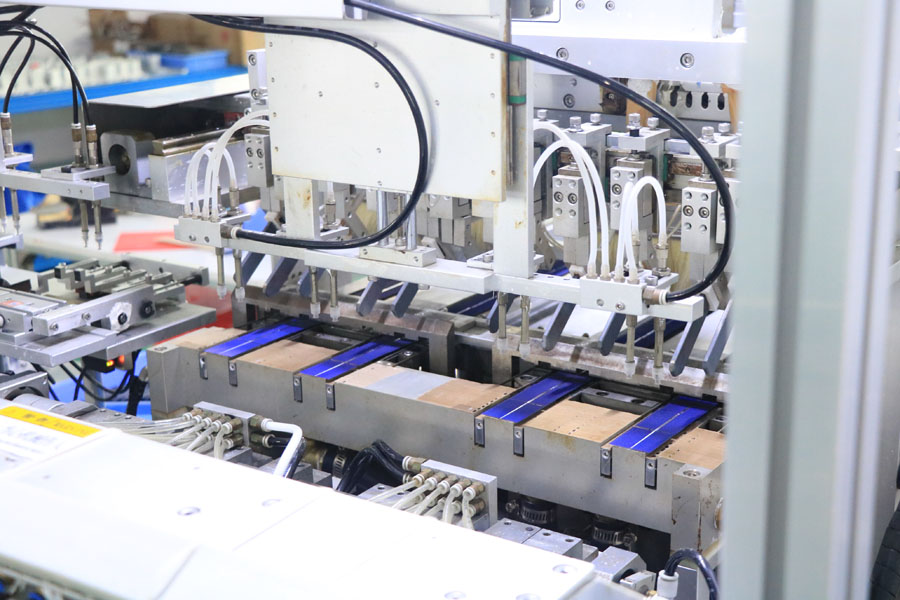

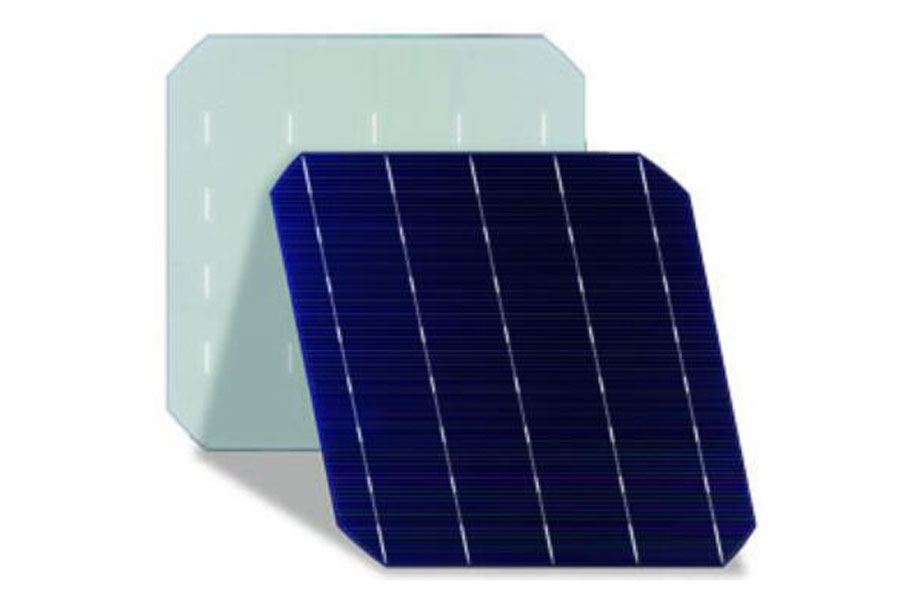

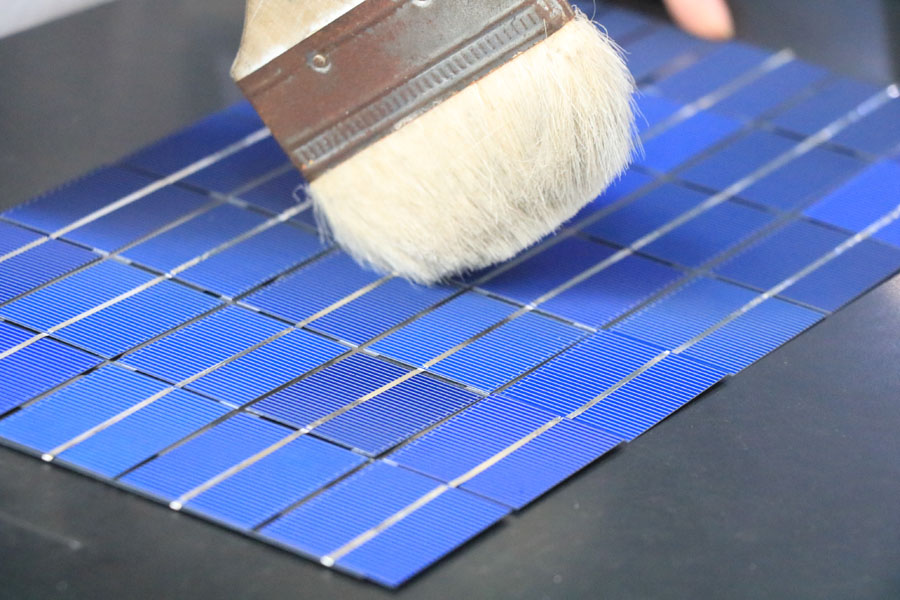

Findy Solar has been a custom solar solution provider and high efficiency custom solar panels manufacturer in China since 2006.