The function of solar panels is to convert the sun’s light energy into electrical energy, and then output direct current to store in the battery. This is the core part of the solar photovoltaic power generation system. The quality and cost of solar panels will directly determine the quality and cost of the entire system. Today we will talk in detail about the performance parameters and types of solar panels.

Solar panel parameters

The performance parameters of solar panels mainly include: short-circuit current, open-circuit voltage, peak current, peak voltage, peak power, fill factor and conversion efficiency.

1. Short-circuit current (isc): When the positive and negative poles of the solar cell are short-circuited and u=0, the current at this time is the short-circuit current of the cell. The unit of short-circuit current is ampere (a), and the short-circuit current changes with the change of light intensity.

2. Open-circuit voltage (uoc): When the positive and negative poles of the solar cell are not connected to the load and i=0, the voltage between the positive and negative poles of the solar cell is the open-circuit voltage. The unit of open-circuit voltage is volt (v). The open circuit voltage of a single solar cell does not change with the increase or decrease of the cell area, and is generally 0.5~0.7V.

3. Peak current (im): Peak current is also called maximum operating current or optimal operating current. Peak current refers to the operating current when the solar cell outputs maximum power, and the unit of peak current is ampere (a).

4. Peak voltage (um): Peak voltage is also called maximum operating voltage or optimal operating voltage. Peak voltage refers to the operating voltage when the solar cell outputs maximum power, and the unit of peak voltage is v. Peak voltage does not change with the increase or decrease of the cell area, and is generally 0.45~0.5V, with a typical value of 0.48V.

5. Peak power (pm): Peak power is also called maximum output power or optimal output power. Peak power refers to the maximum output power of the solar cell under normal working or test conditions, that is, the product of peak current and peak voltage: pm=im×um. The unit of peak power is w (watt). The peak power of solar cells depends on the solar irradiance, solar spectrum distribution and the working temperature of the cell. Therefore, the measurement of solar cells should be carried out under standard conditions. The measurement standard is the European Commission’s Standard 101, which has the following conditions: irradiance lkw/㎡, spectrum aml.5, and test temperature 25℃.

6. Fill factor (ff): Fill factor, also called curve factor, refers to the ratio of the maximum output power of a solar cell to the product of the open circuit voltage and the short circuit current. The calculation formula is ff=pm/(isc×uoc). Fill factor is an important parameter for evaluating the output characteristics of solar cells. The higher its value, the more rectangular the output characteristics of the solar cell are, and the higher the photoelectric conversion efficiency of the cell is.

The series and parallel resistances have a great influence on the fill factor. The smaller the series resistance of the solar cell, the larger the parallel resistance, and the larger the coefficient of the fill factor. The coefficient of the fill factor is generally between 0.5 and 0.8, and can also be expressed as a percentage.

7. Conversion efficiency (η): Conversion efficiency refers to the ratio of the maximum output power of a solar cell when it is illuminated to the solar energy power irradiated on the cell. That is: η=pm (peak efficiency of the cell)/a (area of the cell) × pin (incident light power per unit area), where pin=lkw/㎡=100mw/cm2.

Types of solar panels

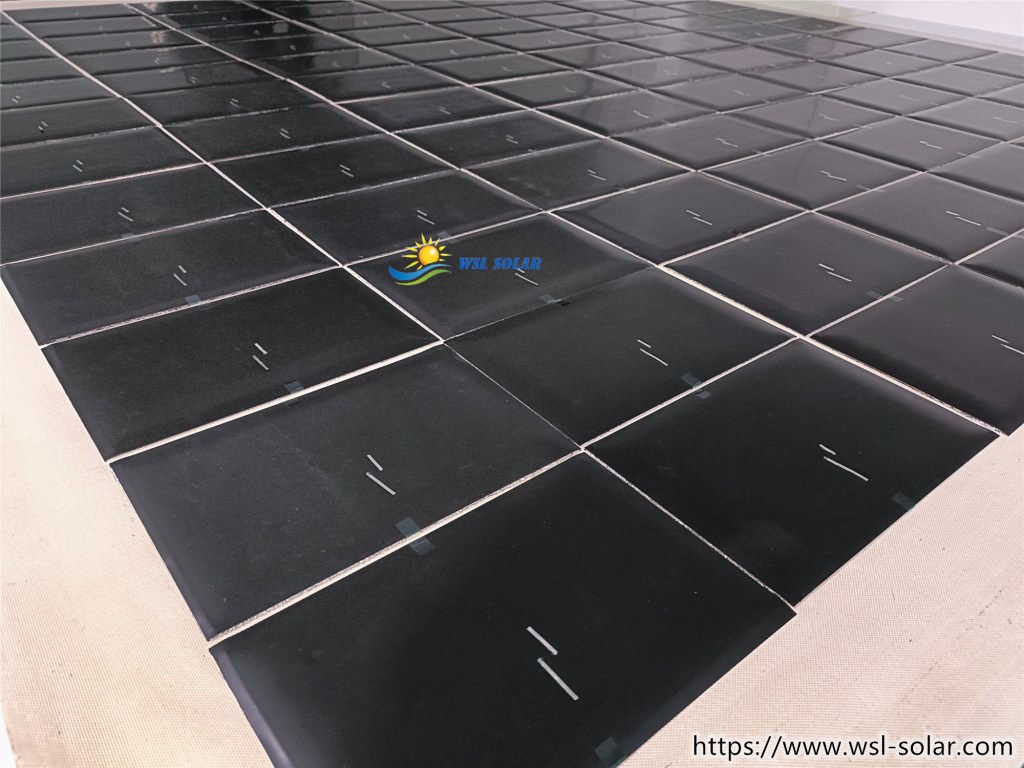

1. Monocrystalline silicon photovoltaic cells

The photoelectric conversion efficiency of monocrystalline silicon solar cells is about 23%, and the highest reaches 26%. This is the highest photoelectric conversion efficiency among all types of solar cells at present, but the production cost is very high, so it cannot be widely and generally used. Since monocrystalline silicon is generally encapsulated with tempered glass and waterproof resin, it is sturdy and durable, and its service life can generally reach 15 years, and up to 25 years.

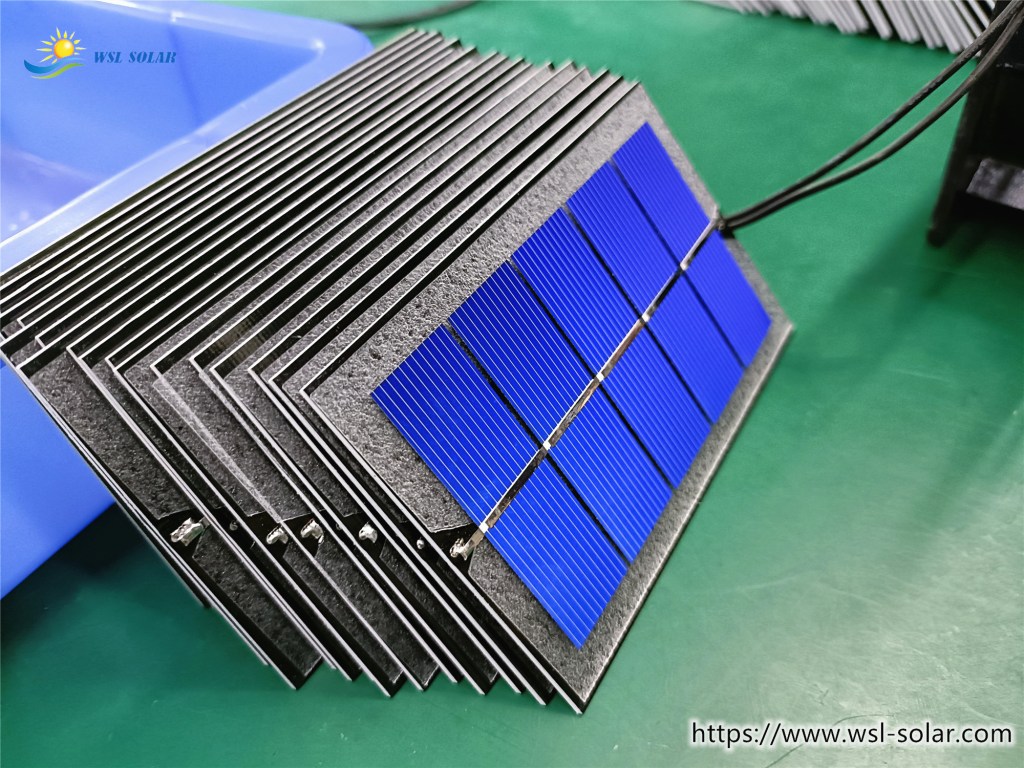

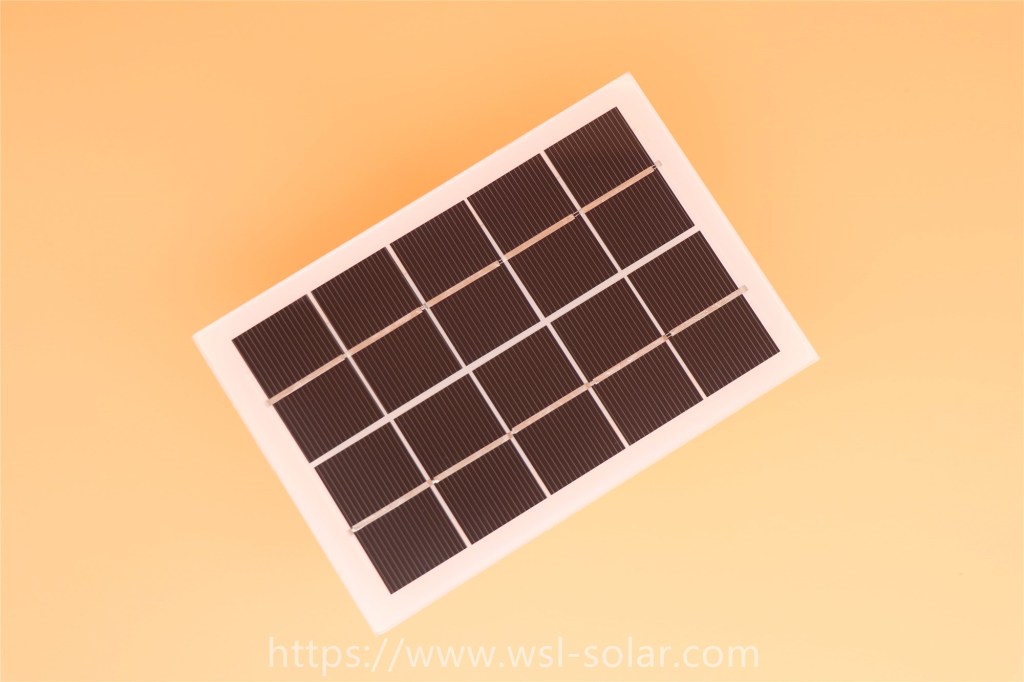

2. Polycrystalline silicon photovoltaic cells

The production process of polycrystalline silicon solar cells is similar to that of monocrystalline silicon solar cells, but the photoelectric conversion efficiency of polycrystalline silicon solar cells is much lower, and its photoelectric conversion efficiency is about 20%. In terms of production cost, it is cheaper than monocrystalline silicon solar cells, the material is simple to manufacture, and it saves electricity consumption. The total production cost is low, so it has been widely developed. In addition, the service life of polycrystalline silicon solar cells is also shorter than that of monocrystalline silicon solar cells. In terms of performance-price ratio, monocrystalline silicon solar cells are slightly better.

3. Amorphous silicon photovoltaic cells

Amorphous silicon solar cells are a new type of thin-film solar cells that appeared in 1976. They are completely different from single-crystal silicon and polycrystalline silicon solar cells in terms of manufacturing method. The process is greatly simplified, silicon material consumption is very low, and power consumption is lower. Its main advantage is that it can generate electricity even under weak light conditions. However, the main problem with amorphous silicon solar cells is that the photoelectric conversion efficiency is low, about 10%, and it is not stable enough. As time goes by, its conversion efficiency decays.

4. Multi-element photovoltaic cells

Multi-element solar cells refer to solar cells that are not made of single-element semiconductor materials. There are many varieties of research in various countries, most of which have not yet been industrialized. The main ones are as follows:

1) Cadmium sulfide solar cells;

2) Gallium arsenide solar cells;

3) Copper indium selenide solar cells (new multi-element bandgap gradient Cu (In, Ga) Se2 thin film solar cells.

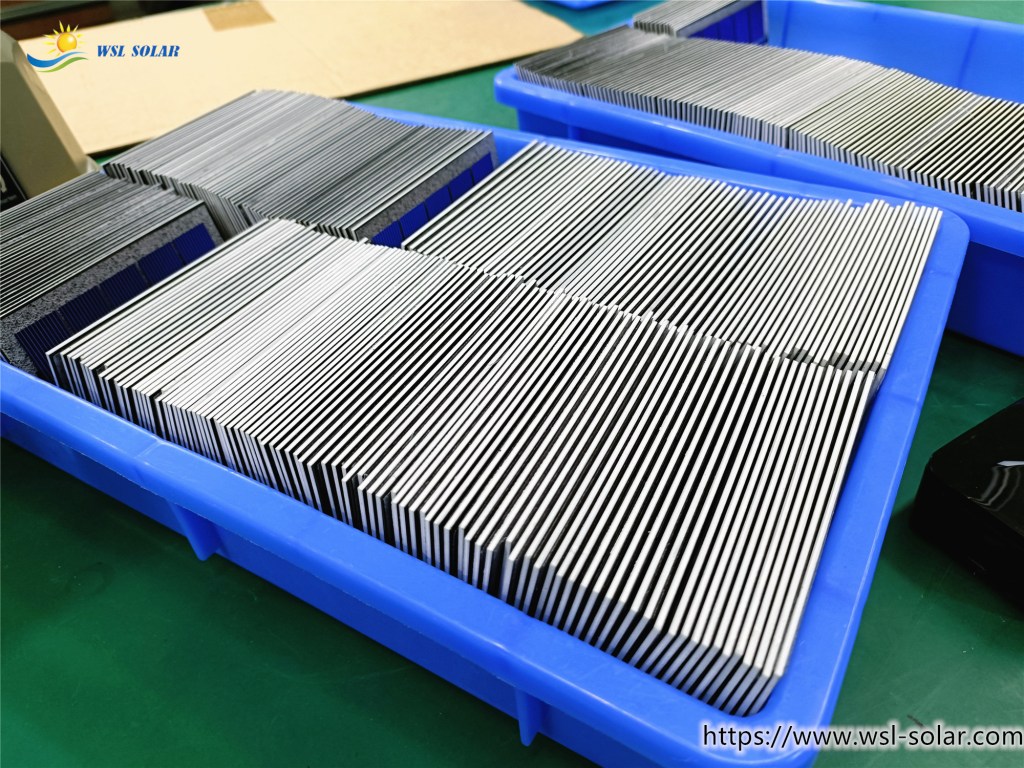

The above is an introduction to the performance parameters and types of solar panels. In addition, packaging is a key step in the production of solar cells. Without a good packaging process, no matter how good the battery is, it will not produce a good solar panel. The packaging of the battery can not only ensure the life of the battery, but also enhance the battery’s resistance, so the packaging quality of the solar panel is very important.

WSL Solar has been a quality and professional manufacturer of custom solar panels, solar mini panels, IoT solar panels and solar solution provider in China since 2006.