When it comes to solar panels, the type of solar cell used is critical. There are several different types of solar cells on the market, each with its own unique characteristics.

Crystalline Silicon Solar Cells (Mono & Poly)

Crystalline silicon solar cells, which are currently the most common, come in two types: monocrystalline and polycrystalline. Monocrystalline solar cells are more efficient, with an efficiency range of 20% – 24%, while polycrystalline solar cells have an efficiency range of 18% – 20%. Additionally, monocrystalline solar cells are more expensive than polycrystalline ones. However, as technology improves and production costs decrease, the price difference between the two is becoming less significant.

Monocrystalline Solar Cell

IBC Solar Cells

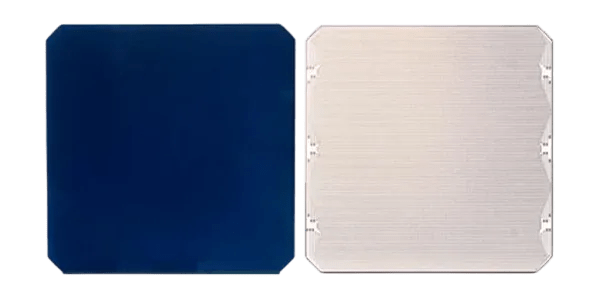

IBC (Interdigitated Back Contact) solar cell transfers all the electrode grid lines on the front side of the solar cell to the back side of the solar cell. IBC solar cell mainly improves conversion efficiency through structural changes. This not only brings more effective power generation area to users, but also helps improve power generation efficiency and makes the appearance more beautiful. IBC solar cells are the most efficient solar cells on the market, with an efficiency of over 23%. However, they are also the most expensive.

IBC Solar Cell

When choosing a solar panel, it’s important to consider the specific needs of the application. For small solar panels with limited use areas, monocrystalline solar panels are a better option. Encapsulation methods for crystalline silicon solar panels include glass lamination, PET, ETFE lamination, or epoxy. For IBC solar panels, encapsulation methods include PET or ETFE lamination.

Remember, choosing the right solar cell is essential for the overall efficiency and effectiveness of your solar panel.

Source of origin: https://chinasolar-panel.com