12BB (12 busbar) solar cells use multi-busbar (MBB) technology to collect electricity from the solar cell, which increases efficiency and power output compared to traditional designs with fewer busbars. The increased number of busbars shortens the electrical path, which reduces resistance and power loss. This also enhances reliability, making the cells more resistant to cracking and better at performing in low-light conditions.

1. The Core Concept: What are Busbars (BB)?

A standard solar cell generates electricity when sunlight hits it. This electricity needs to be collected and channeled out of the cell. This is the job of the fingers and the busbars.

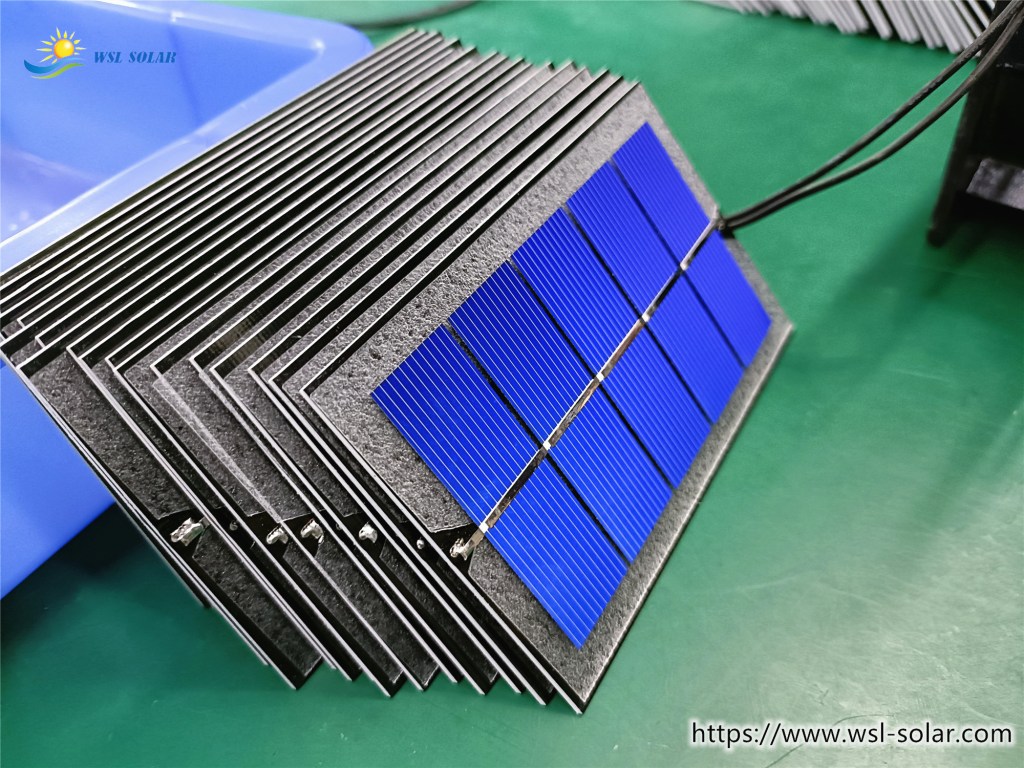

- Fingers: The very fine, hair-thin lines that cover the cell. They collect the electricity.

- Busbars (BBs): The wider, more prominent lines that run perpendicular to the fingers. They act as the main “highways” that gather the current from all the fingers and transport it to the tabbing wires, which connect the cells together in a module.

So, a 12BB cell simply has 12 of these main silver highways on its surface.

2. The Evolution: From 2BB to 5BB, 9BB, 12BB, and Beyond

The number of busbars has been steadily increasing over the years as manufacturing technology has advanced.

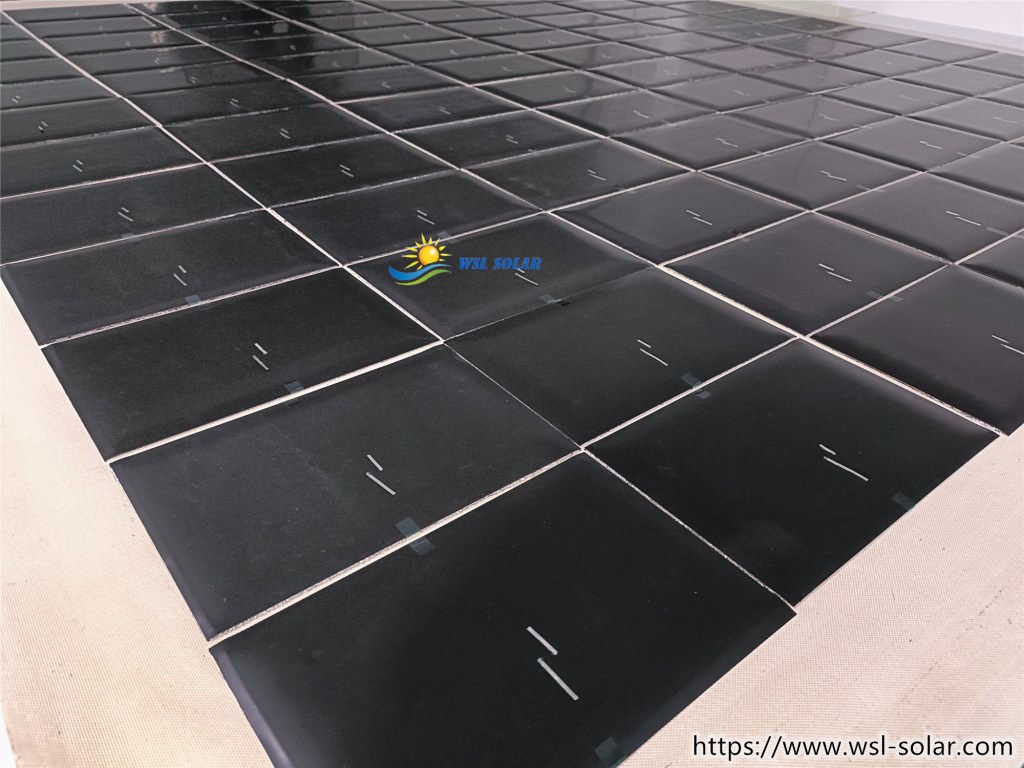

- 2BB to 5BB: This was the standard for a long time. Fewer, thicker busbars were easier to manufacture.

- 9BB, 12BB, 15BB, etc.: The current industry trend is to move to more, but thinner and finer, busbars.

3. Key Advantages of 12BB Solar Cells

Why is moving to more busbars beneficial? The primary goals are higher efficiency and increased reliability.

1). Higher Efficiency & Power Output

- Reduced Electrical Resistance: Electricity has to travel a shorter distance from where it’s generated to the nearest busbar. Shorter travel paths mean less energy is lost as heat (a phenomenon called resistive loss).

- Better Current Collection: With more collection points, the cell can collect current more uniformly and effectively, especially in low-light conditions.

- Reduced Shading: Although there are more busbars, each one is made much thinner. The total amount of area on the cell covered by silver (which blocks sunlight) is reduced. This means more active silicon area is exposed to light.

2). Improved Reliability and Durability

- Lower Mechanical Stress: The tabbing wires (ribbons) that connect the cells are also made thinner. Thinner ribbons are more flexible, which reduces the stress on the cell during thermal expansion and contraction (from daily heating/cooling cycles). This lowers the risk of micro-cracks.

- Better Performance with Micro-Cracks: If a micro-crack does occur, it is less likely to completely isolate a section of the cell because there are more busbars providing alternative paths for the current to flow. This helps maintain the module’s power output over its lifetime.

3). Cost-Effectiveness

- While using 12 busbars requires more precise manufacturing, it often uses less silver overall. Silver is a significant cost driver in solar cell production. By using finer lines, manufacturers save on material costs while boosting performance.

4. Comparison Table: BB Evolution

| Feature | Traditional (e.g., 5BB) | Advanced (12BB) | Benefit of 12BB |

|---|---|---|---|

| Number of Busbars | Fewer (e.g., 5) | More (12) | Shorter current path, less resistance |

| Busbar Width | Thicker | Thinner & Finer | Less shading, more light capture |

| Tabbing Ribbon | Thicker | Thinner & More Flexible | Reduced risk of micro-cracks |

| Efficiency | Lower | Higher | More power from the same size cell/roof |

| Reliability | Standard | Improved | Better long-term performance and durability |

Conclusion

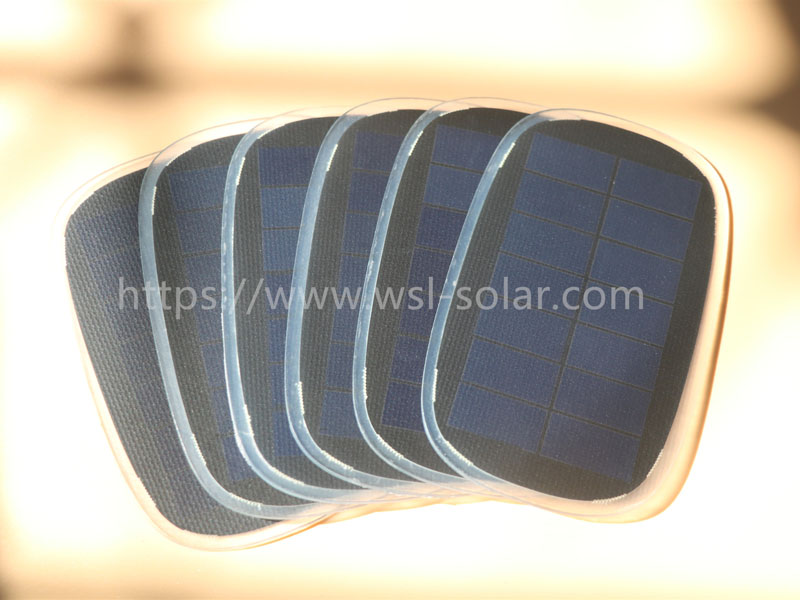

12BB solar cells represent a key incremental innovation in photovoltaic technology. They are not a fundamentally new type of cell (like PERC or HJT), but rather an optimization of the electrical grid design on mainstream cell types.

This design shift is a major reason why the power ratings of solar panels have been steadily increasing over the past few years, with many premium residential and commercial panels now utilizing 12BB or even higher busbar count cells (like 16BB) to achieve higher efficiencies and better reliability.

In short: 12BB cells are a more refined, efficient, and robust version of the standard silicon solar cell, leading to better-performing and longer-lasting solar panels.

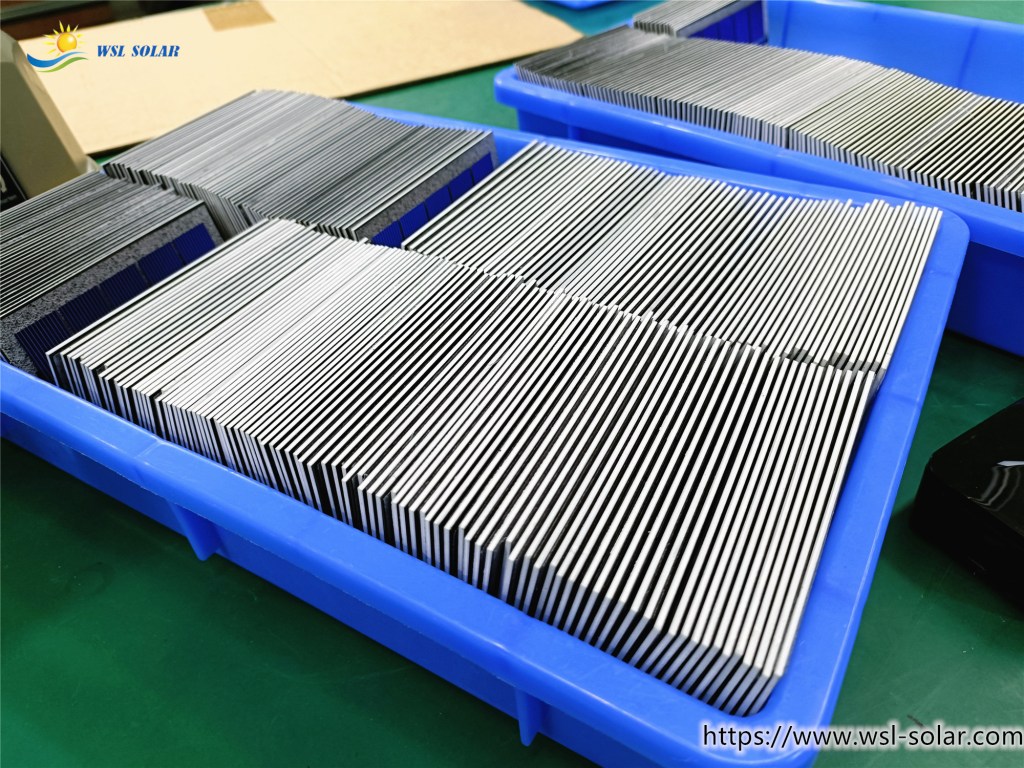

Posted by Carrie Wong / WSL Solar

WSL Solar has been a quality and professional manufacturer of custom solar panels, solar mini panels, IoT solar panels and solar solution provider in China since 2006.

https://www.wsl-solar.com