Key Features:

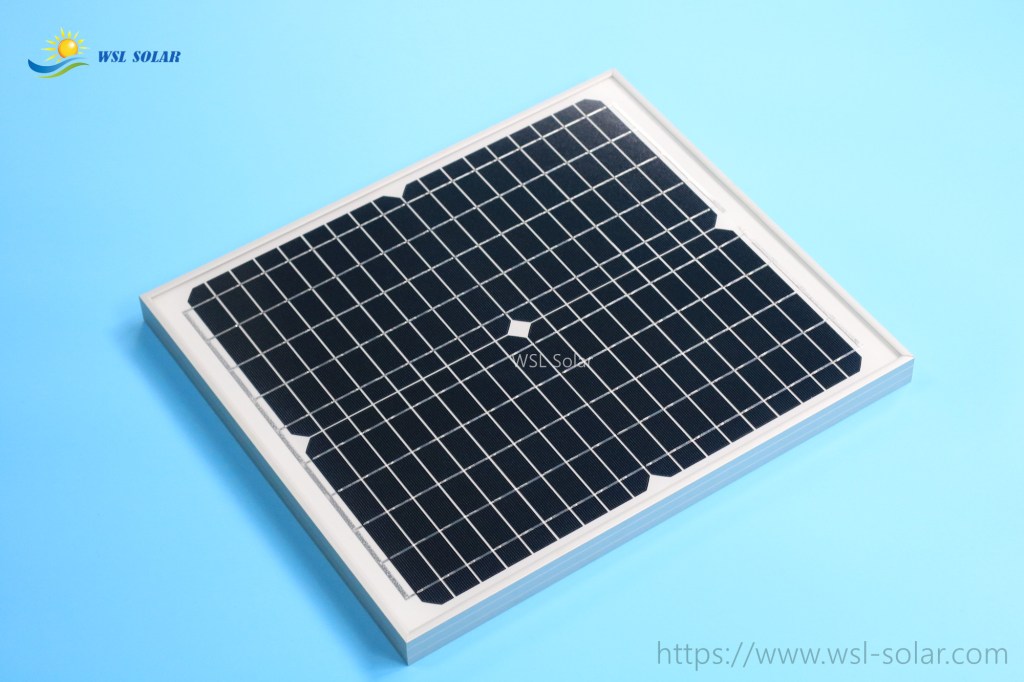

– Utilize high efficiency mono PERC solar cell, up to 22.5% efficiency

– Laminated by tempered glass, rigid, durable and long lasting

– Waterproof, scratch resistant, and UV resistant

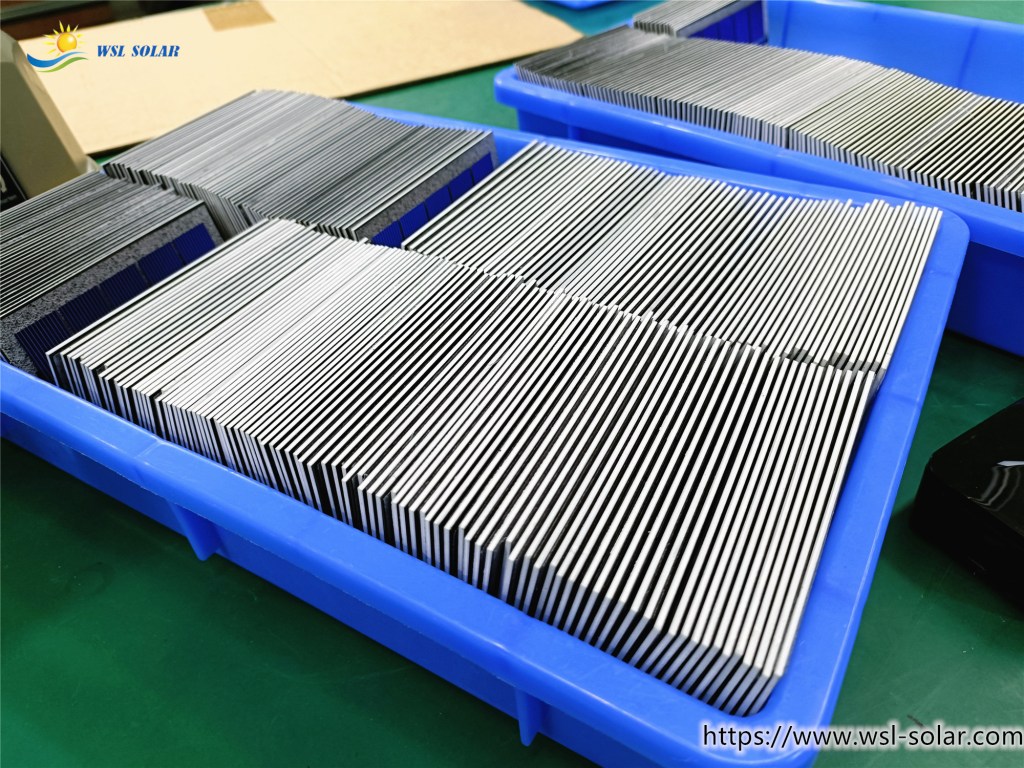

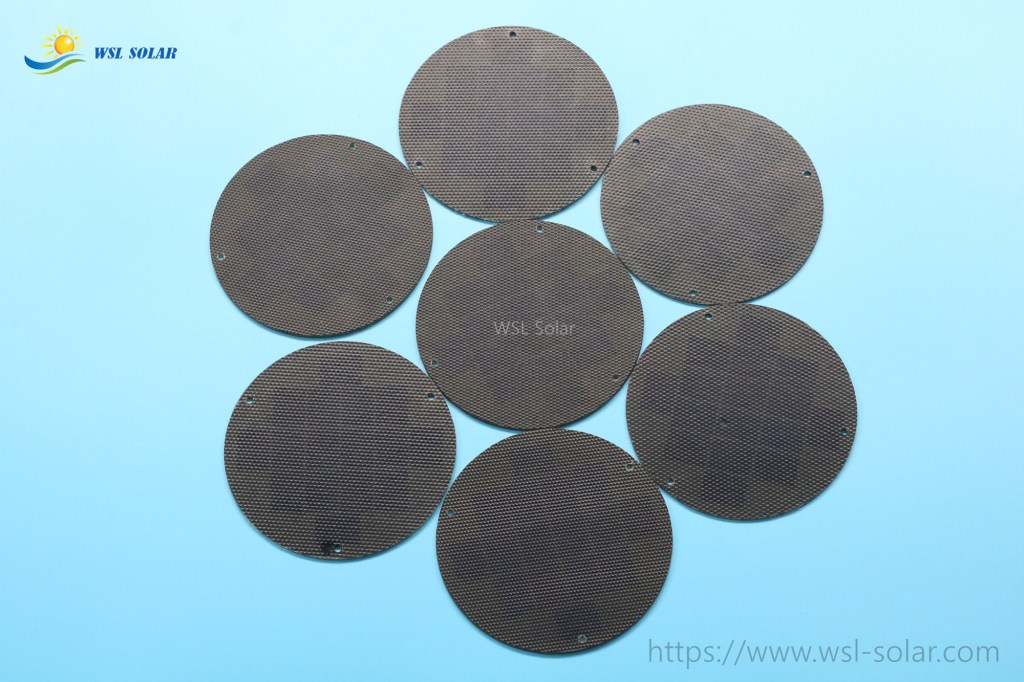

– Customized solar panels for industrial use

Description:

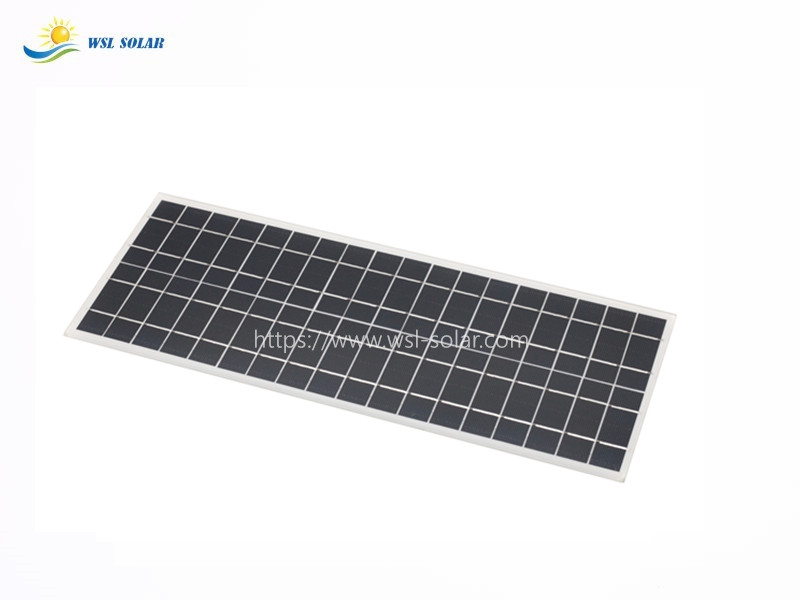

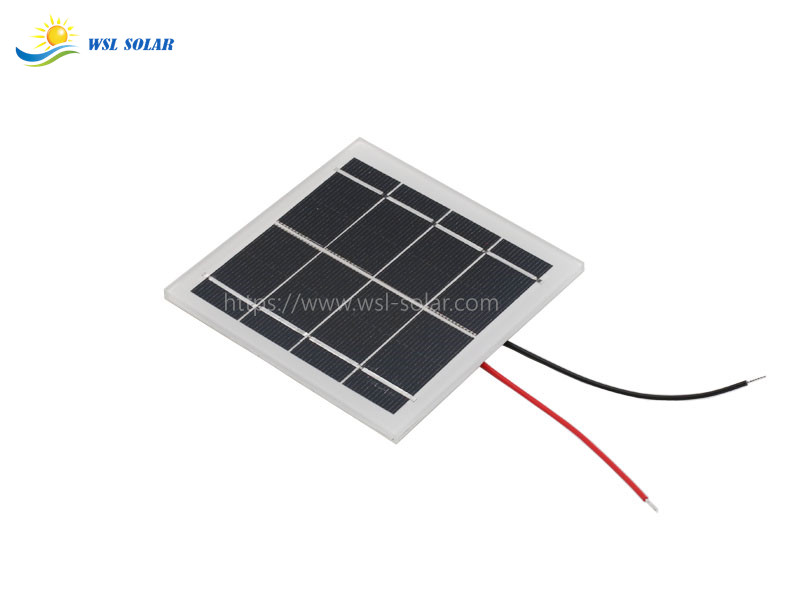

4.4V 1.3W Solar Panel

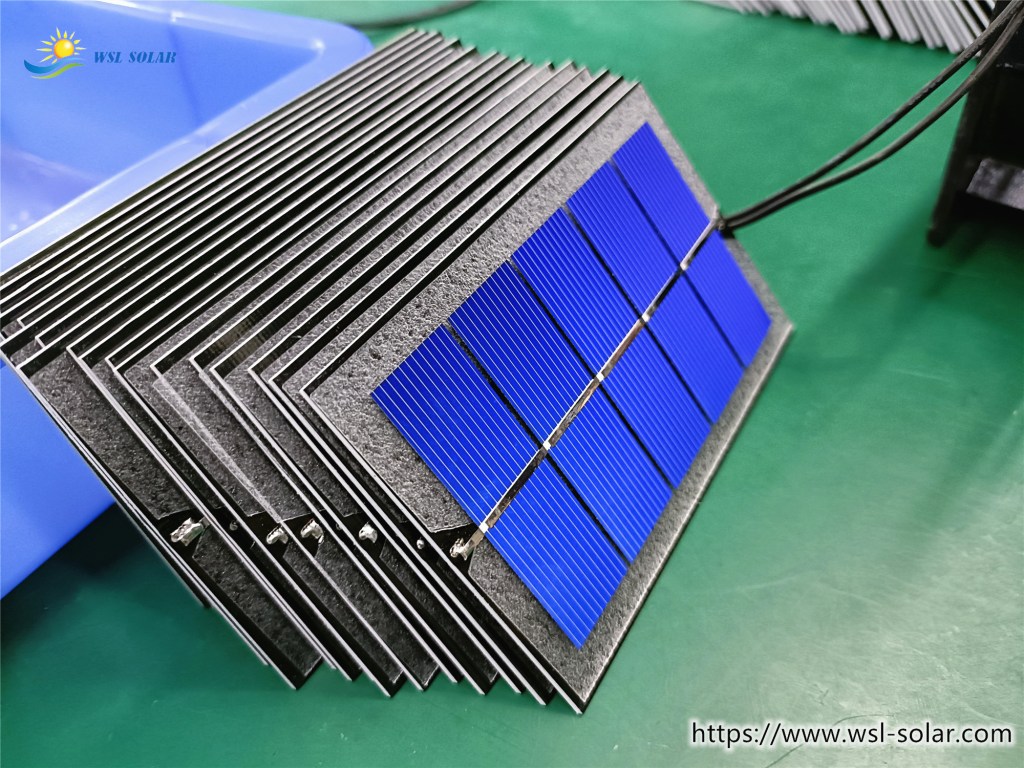

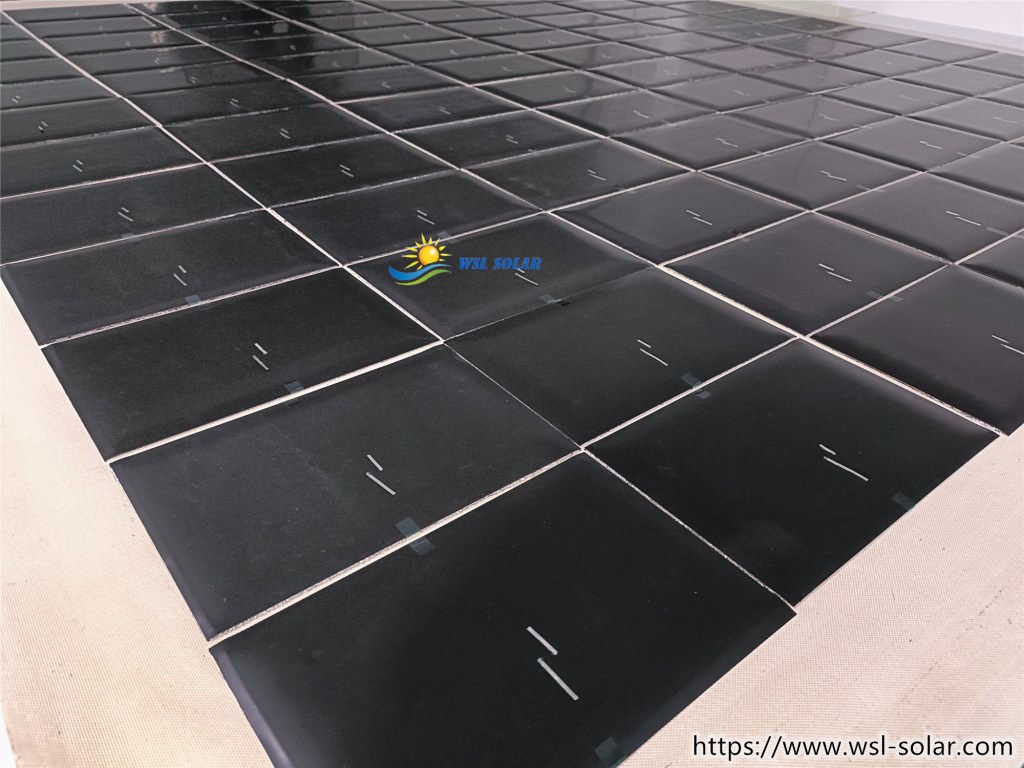

This custom solar panel utilizes high efficiency mono PERC solar cells with efficiency up to 22.5%, to ensure its high output. It is laminated by tempered glass to protect the solar cells inside, making it rigid, durable and long lasting. This rigid solar panel is waterproof, scratch resistant, and UV resistant, specially designed for long term outdoor use in any challenging condition.

Applications:

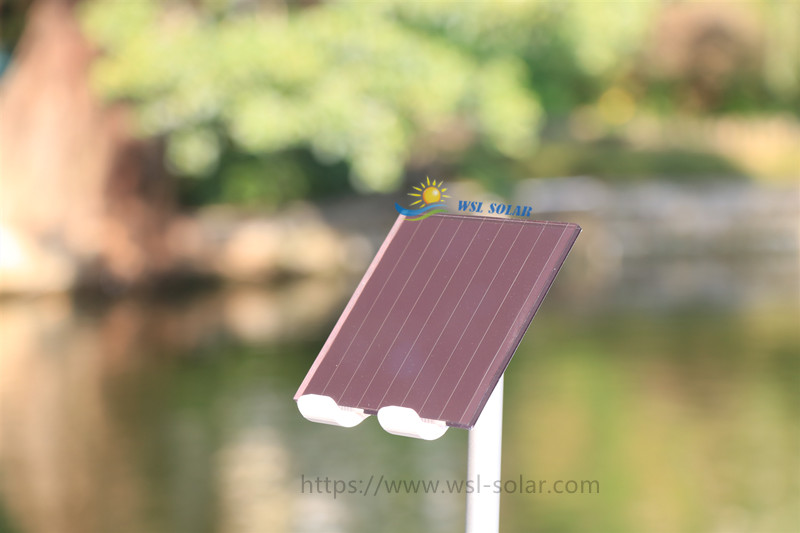

Tempered glass solar panels are widely used in IoT applications, marine buoys, wireless sensors, traffic warning devise, GPS devices, asset tracking, electric fence chargers, outdoor lighting systems, weather monitoring systems etc.

Solar Panel Specification

| Item No. | WSL-C033 |

| Solar Panel Size | 95x95x4.8mm |

| Peak Power (Pmax) | 1.3W |

| Voltage at Pmax (Vmp) | 4.4V |

| Current at Pmax (Imp) | 295mA |

| Open Circuit Voltage (Voc) | 5.2V |

| Short Circuit Current (Isc) | 320mA |

| Solar Cell Type | Mono PERC Solar Cell |

| Power Tolerance | ±5% |

| Encapsulation method | 3.2mm Tempered glass |

| Back sheet | TPT |

| Product Warranty | 5 Years |

| Lead time | 25 Days |

| Storage temperature | -40°C ~ 85°C |

| Working temperature | -40°C ~ 85°C |

| Standard Test Conditions (STC) | 1000W/m2, 1.5AM, 25°C Cell temperature |

Click here to watch the video of this type of custom solar panels.

View More Custom Solar Panels

5V Solar Panels | 6V Solar Panels | 9V Solar Panels

WSL Solar has been a quality and professional manufacturer of custom solar panels and solar solution provider in China since 2006.

Source of origin: https://www.wsl-solar.com/4V-1W-Solar-Panel.html