Crystalline silicon solar panels and amorphous silicon solar panels are two distinct types of photovoltaic technologies, differing in their structure, efficiency, cost, and applications.

Crystalline Silicon Solar Panel

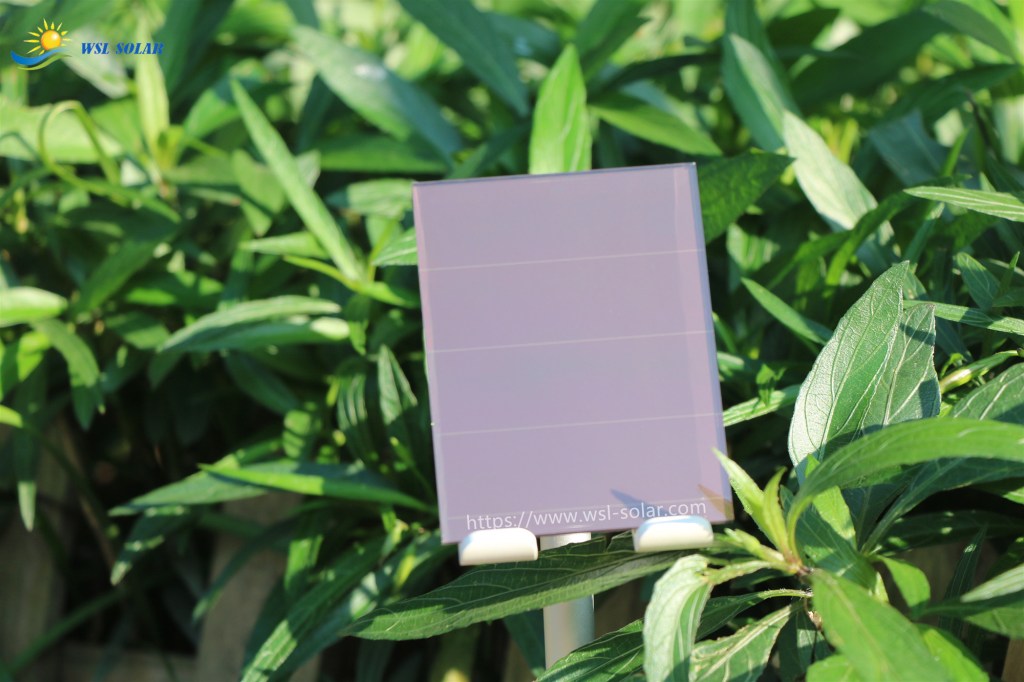

Amorphous Silicon Solar Panel

Here’s a breakdown of the key differences:

1. Structure and Composition

– Crystalline Silicon Solar Panels:

– Made from silicon atoms arranged in a highly ordered, crystalline structure.

– Two main types:

– Monocrystalline Silicon**: Made from a single crystal structure, giving it a uniform appearance and high efficiency.

– Polycrystalline Silicon**: Made from multiple silicon crystals, resulting in a less uniform appearance and slightly lower efficiency.

– Amorphous Silicon Solar Panels:

– Made from non-crystalline (amorphous) silicon, where atoms are arranged in a disordered, random structure.

– Typically deposited as a thin film on substrates like glass, metal, or plastic.

2. Efficiency

– Crystalline Silicon:

– Higher efficiency due to the ordered structure, which allows for better electron movement.

– Monocrystalline panels: ~20-23% efficiency.

– Polycrystalline panels: ~18-20% efficiency.

– Amorphous Silicon:

– Lower efficiency due to the disordered structure, which hinders electron movement.

– Typically ~6-10% efficiency.

3. Cost

– Crystalline Silicon:

– Generally more expensive to produce due to the energy-intensive manufacturing process and high-purity silicon requirements.

– Amorphous Silicon:

– Cheaper to produce because it uses less silicon and can be manufactured using simpler processes like thin-film deposition.

4. Flexibility and Applications

– Crystalline Silicon:

– Rigid and heavy, making them suitable for traditional rooftop installations and large-scale solar farms.

– Amorphous Silicon:

– Lightweight and flexible, enabling use in unconventional applications like curved surfaces, portable devices, and building-integrated photovoltaics (BIPV).

5. Performance in Low Light and High Temperatures

– Crystalline Silicon:

– Performs better under standard test conditions but can lose efficiency in high temperatures.

– Amorphous Silicon:

– Performs better in low-light conditions (e.g., cloudy weather) and is less affected by high temperatures.

6. Lifespan and Durability

– Crystalline Silicon:

– Longer lifespan (25-30 years or more) and higher durability.

– Amorphous Silicon:

– Shorter lifespan and may degrade faster over time (e.g., due to light-induced degradation).

7. Aesthetic Appeal

– Crystalline Silicon:

– Monocrystalline panels have a sleek, black appearance, while polycrystalline panels have a blue, speckled look.

– Amorphous Silicon:

– Thin-film panels have a uniform, dark appearance and can be integrated into building materials for a more aesthetic look.

Summary Table:

| Feature | Crystalline Silicon | Amorphous Silicon |

| Structure | Ordered crystal structure | Disordered, random structure |

| Efficiency | 18-23% | 6-10% |

| Cost | Higher | Lower |

| Flexibility | Rigid | Flexible |

| Applications | Rooftops, solar farms | BIPV, portable devices |

| Low-Light Performance | Moderate | Better |

| Lifespan | 25-30+ years | Shorter |

| Aesthetic | Sleek black(mono) or blue speckled (poly) | Uniform, dark appearance |

In summary, crystalline silicon panels are more efficient and durable but costlier, while amorphous silicon panels are cheaper, flexible, and better suited for specific applications like BIPV or portable devices. The choice depends on the specific needs and constraints of the project.

Posted by Carrie Wong / WSL Solar

WSL Solar has been a quality and professional manufacturer of custom solar panels, solar mini panels, IoT solar panels and solar solution provider in China since 2006.