When we produce customized solar panels according to the specific needs of customers, we usually need to cut the solar cells into small pieces, and then connect the small pieces of solar cells in series or parallel as needed to form a solar cell string. Then, different numbers of solar cell strings are connected according to the required electrical performance to form a solar panel.

According to different types of solar cells and different production processes, there are usually two ways to connect solar cells.

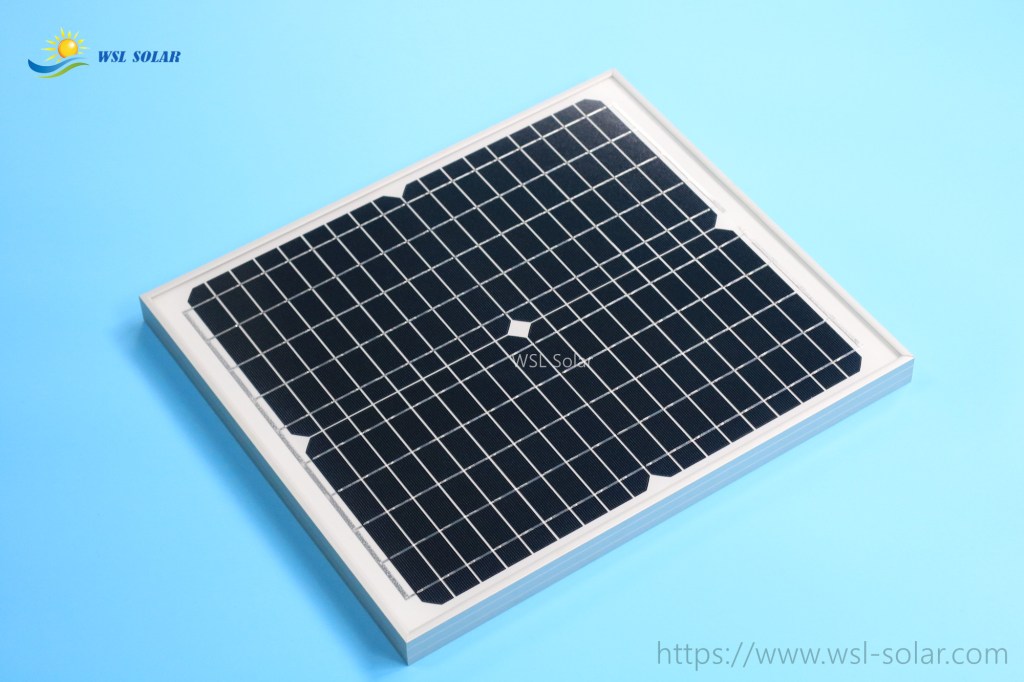

For traditional crystalline silicon solar cells, in mass production, the connection method is usually through an automatic string welding machine. The positive electrode of one solar cell is connected to the negative electrode of the adjacent solar cell with a soldering ribbon to form a solar cell string. Using a string welding machine can not only greatly improve production efficiency and save labor costs, but also ensure product consistency.

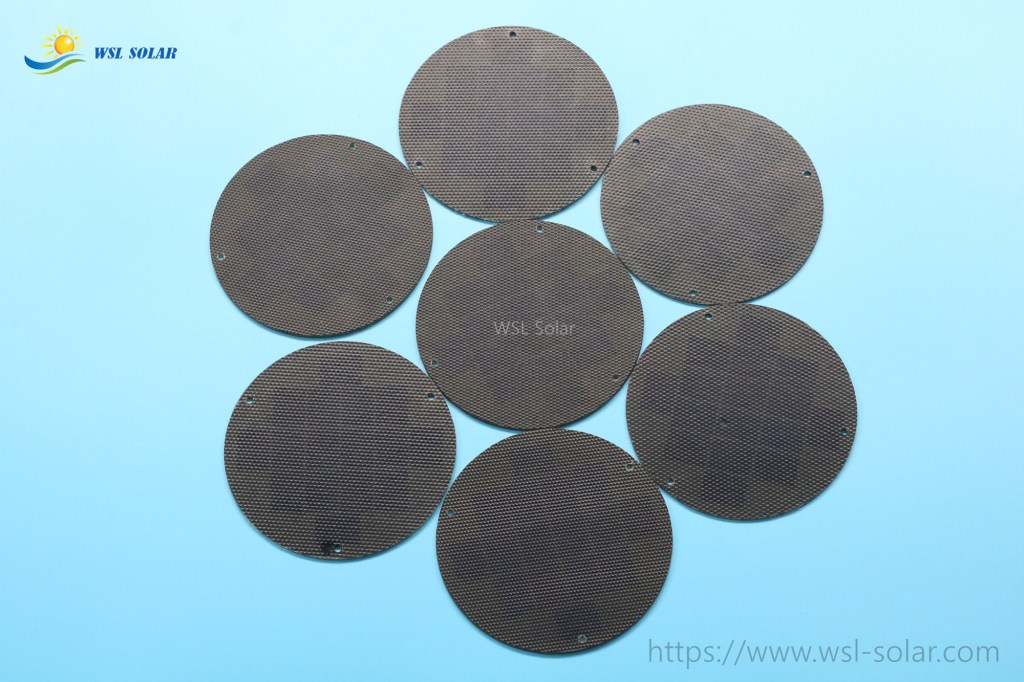

For back-contact solar cells, in mass production, the connection method is usually to attach the solar cells to the PCB board through an SMT machine in a designed way, and then solder the solar cells together through reflow soldering. Or use an automatic string welding machine to connect in series or parallel in the same way as traditional crystalline silicon solar cells.

WSL Solar has been a quality and professional manufacturer of custom solar panels, solar mini panels, IoT solar panels and solar solution provider in China since 2006.

https://www.wsl-solar.com

Source of origin: https://www.wsl-solar.com/Product_News/2023/1130/how-to-connect-solar-cells.html